astm tear testing|vulcanized rubber tear test : importing ASTM's fatigue and fracture standards provide the appropriate procedures for carrying out fatigue, fracture, and other related tests on specified materials. These tests are conducted to examine and evaluate the behavior, susceptibility, and extent of resistance of certain materials to sharp-notch tension, tear, axial fatigue, strain-controlled . Eppendorfs pipette families Research plus and Reference 2 fully meet the testing requirements and did not show any signs of damage or impairment following the testing.Keep the boxes cracked open in the autoclave. It’s enough to just prop the lid open with the .

{plog:ftitle_list}

Come avviene il trattamento in autoclave del legno? Possiamo dividere questo trattamento in tre principali fasi: 1) una volta riempita la camera con la quantità di legno prestabilita, viene tolta tutta l’aria, creando il vuoto.

5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service .

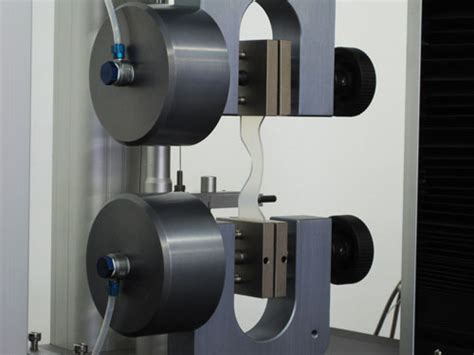

ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test. 5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service due to the generation and propagation of a special type of rupture called a tear. This test method measures the resistance to tearing action.ASTM's fatigue and fracture standards provide the appropriate procedures for carrying out fatigue, fracture, and other related tests on specified materials. These tests are conducted to examine and evaluate the behavior, susceptibility, and extent of resistance of certain materials to sharp-notch tension, tear, axial fatigue, strain-controlled .Type C (right angle) test piece, divided by the thickness of the test piece.3.2.4 Type T or trouser tear strength—the mean or median force, calculated in accordance with procedures in this method, required to propagate a tear.

ASTM's physical and mechanical testing standards provide guides for the proper procedures employed in the determination of the physical, mechanical, and metallographic properties of certain materials, particularly metals and alloys.

1.1 This test method covers the dynamic tear (DT) test using specimens that are 3⁄16 in. to 5⁄8 in. (5 mm to 16 mm) inclusive in thickness. 1.2 This test method is applicable to materials with a minimum thickness of 3⁄16 in. (5 mm).A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and suitability of materials under real-world conditions.

large autoclave pans

vulcanized rubber tear test

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under conditions that might lead to tearing.Scope. 1.1 This test method covers the dynamic tear (DT) test using specimens that are 3⁄16 in. to 5⁄8 in. (5 mm to 16 mm) inclusive in thickness. 1.2 This test method is applicable to materials with a minimum thickness of 3⁄16 in. (5 mm). The Tongue Tear Test (ASTM D2261) is an essential technique for evaluating the tearing strength of textiles and offers insightful data regarding their resilience to tearing across a range of industries.ASTM D624 is a common test method used to determine the tear strength of vulcanized rubber and thermoplastic elastomers. Due to the specimen shapes often used, this test is sometimes called a trouser, angle, or crescent test.

5.1 Vulcanized rubber and thermoplastic elastomers (TPE) often fail in service due to the generation and propagation of a special type of rupture called a tear. This test method measures the resistance to tearing action.ASTM's fatigue and fracture standards provide the appropriate procedures for carrying out fatigue, fracture, and other related tests on specified materials. These tests are conducted to examine and evaluate the behavior, susceptibility, and extent of resistance of certain materials to sharp-notch tension, tear, axial fatigue, strain-controlled .

Type C (right angle) test piece, divided by the thickness of the test piece.3.2.4 Type T or trouser tear strength—the mean or median force, calculated in accordance with procedures in this method, required to propagate a tear.ASTM's physical and mechanical testing standards provide guides for the proper procedures employed in the determination of the physical, mechanical, and metallographic properties of certain materials, particularly metals and alloys.

1.1 This test method covers the dynamic tear (DT) test using specimens that are 3⁄16 in. to 5⁄8 in. (5 mm to 16 mm) inclusive in thickness. 1.2 This test method is applicable to materials with a minimum thickness of 3⁄16 in. (5 mm).A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and suitability of materials under real-world conditions.

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under conditions that might lead to tearing.Scope. 1.1 This test method covers the dynamic tear (DT) test using specimens that are 3⁄16 in. to 5⁄8 in. (5 mm to 16 mm) inclusive in thickness. 1.2 This test method is applicable to materials with a minimum thickness of 3⁄16 in. (5 mm).

large autoclave parts list

tear strength test method

large autoclave pictures

tear initiation strength test

After autoclaving, and when the agar has cooled enough that it's not too hot to touch (about 1 to 1.5hrs), add antibiotics as follows: Ampicillin – add 1ml ampicillin (at 100mg/ml) per liter of agar .

astm tear testing|vulcanized rubber tear test